Airless Spray Guns

Internal Pipe Painting Equipment

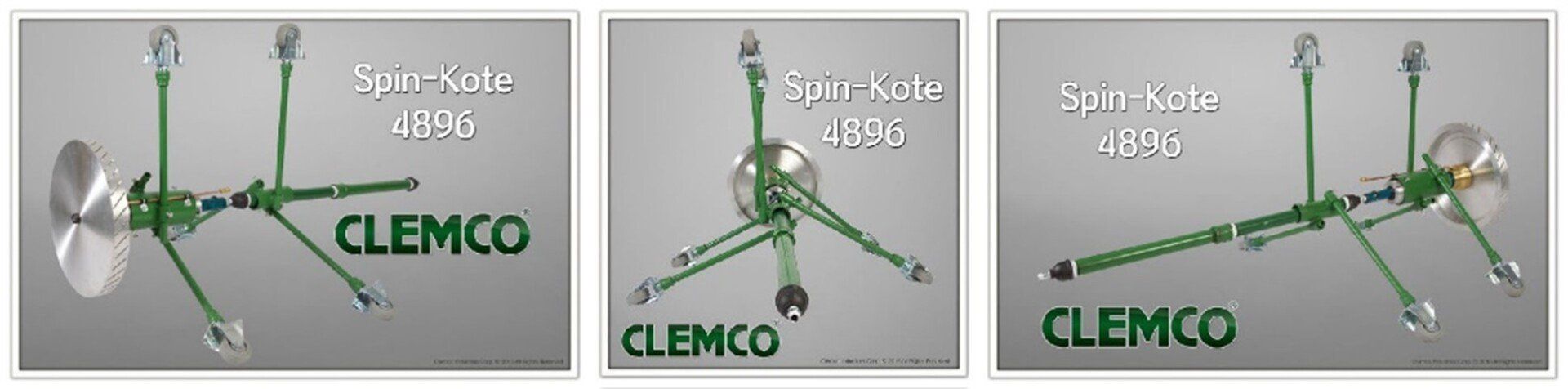

Clemco Spin-Kote Internal Painting System

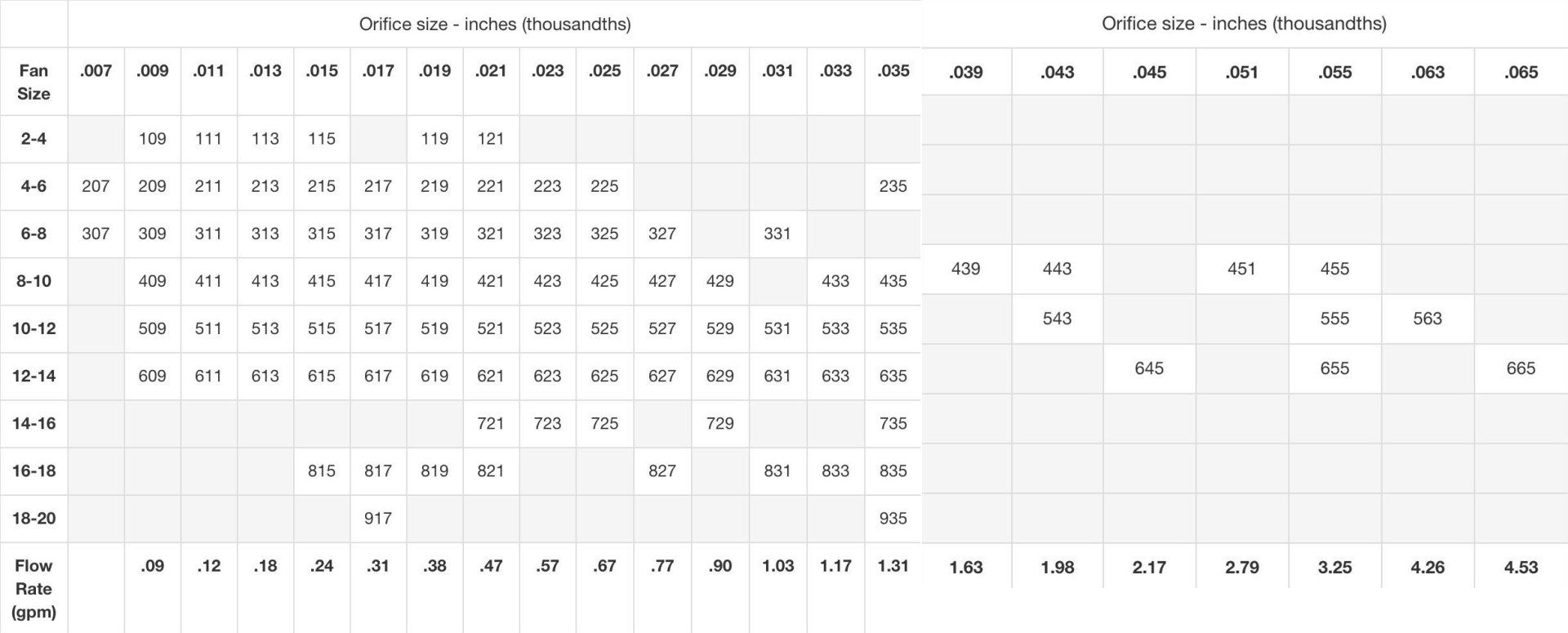

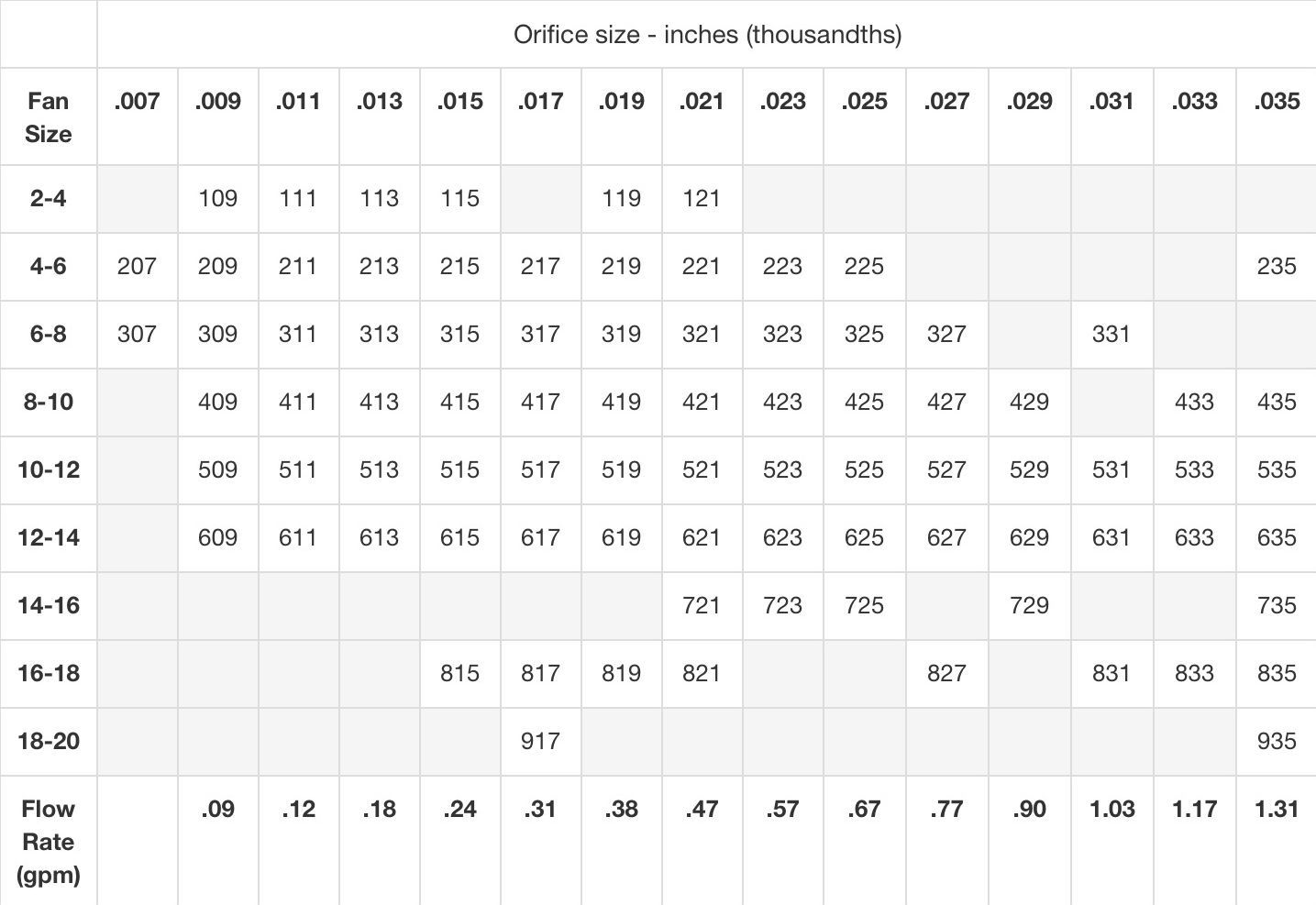

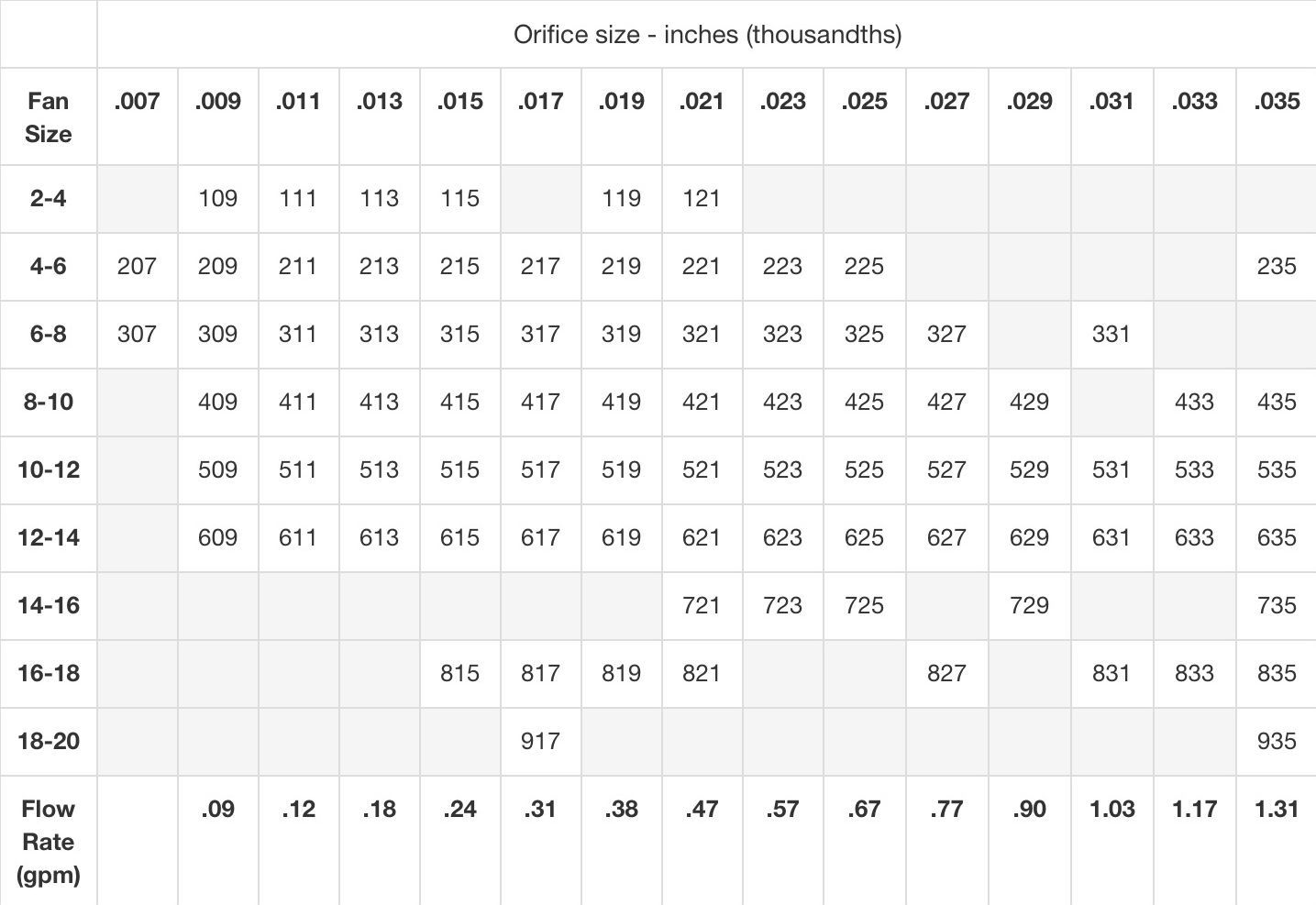

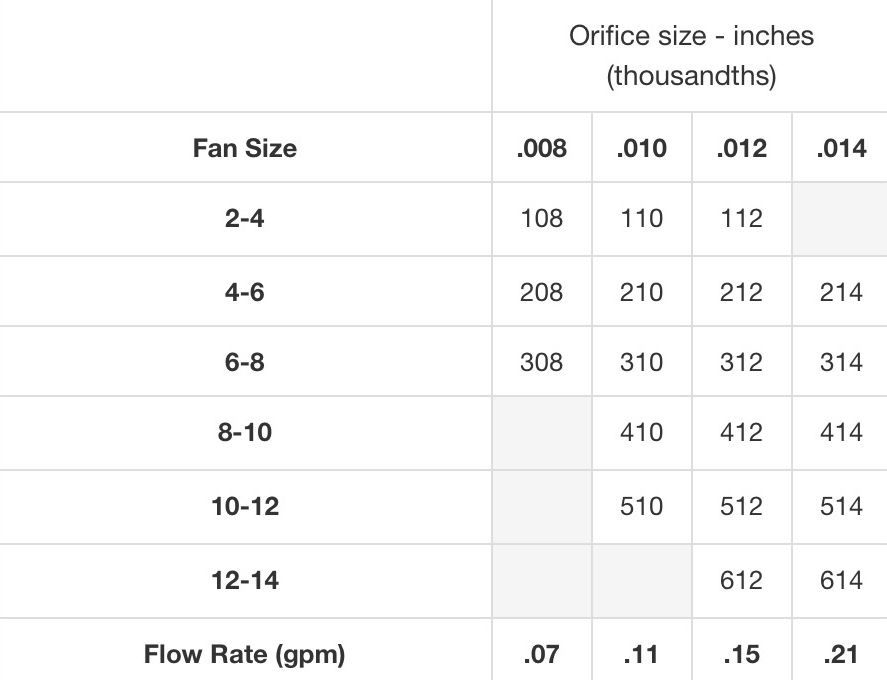

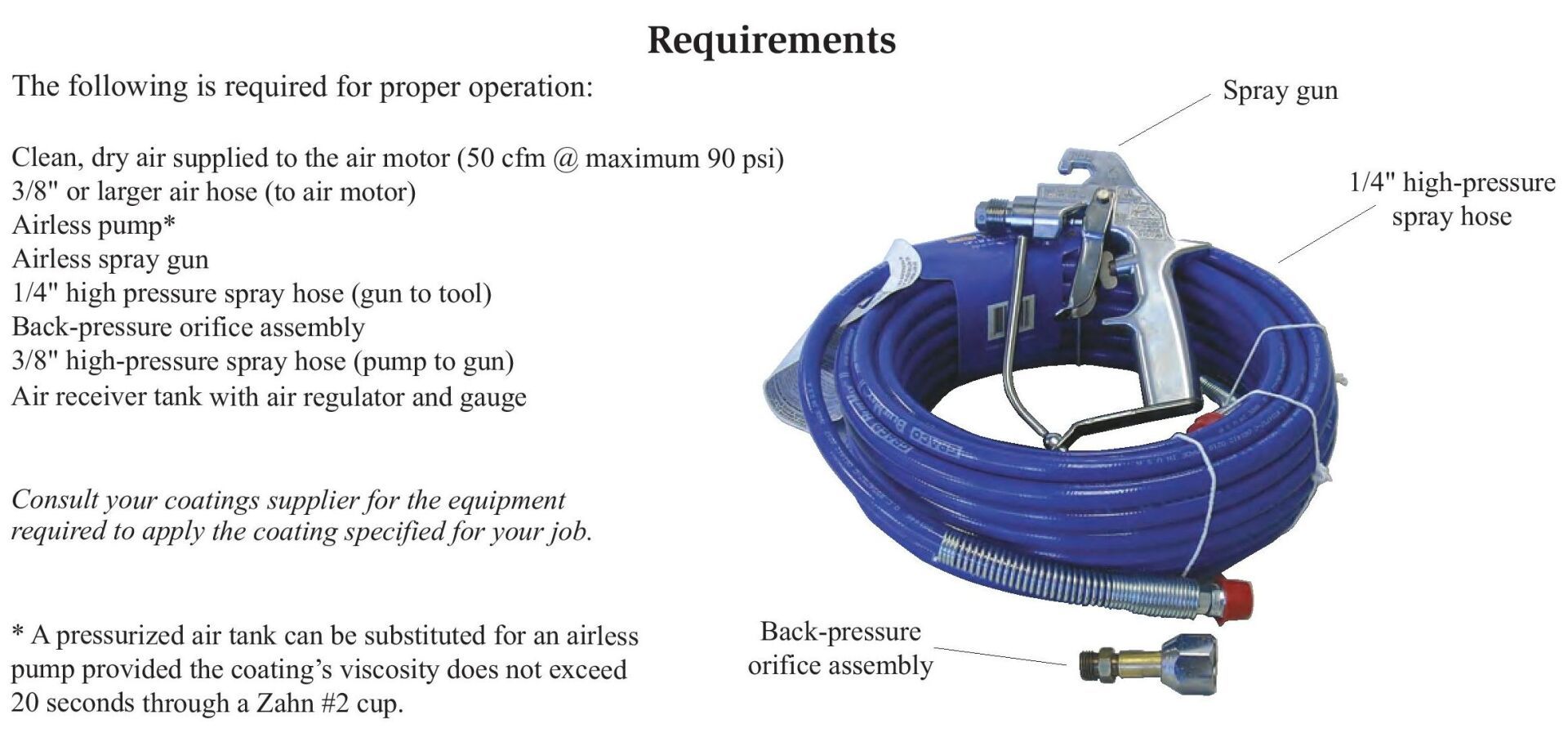

The Clemco Spin-Kote tool allows for you to evenly coat in the interior of pipe and tubing with an inside diameter between 2” – 96” using an airless pump*. Once in operation, the coating is applied 360° by centrifugal force through the spinning spray head. The speed at which the tool is pulled back through the pipe will determine the coating’s wet film thickness and coverage rates. Pre-selected back pressure orifices installed at the gun head and adjustments to the pump’s fluid pressure will allow you to make changes to the volume of coating transferred through the tool. Each tool comes packaged with its appropriate carriage device so that it can centered within the pipe.

Advantages

- Manually Adjustable, Easy to Use Tools

- Suit a Variety of Coatings

- Increase Production

- Simple Design = Reliable

- Increase Production

- Simple Design = Reliable Performance

- No Need to Rotate the Pipe

- 95% Transfer Efficiency

Spin-Kote Options

27020 Spin-Kote 25 2” – 5” ID Pipe

27021 Spin-Kote 512 5” – 12” ID Pipe

27022 Spin-Kote 817 8” – 17” ID Pipe

27023 Spin-Kote 1236 12” – 36” ID Pipe

27024 Spin-Kote 4896 48” – 96” ID Pipe

Spin-Kote Accessories

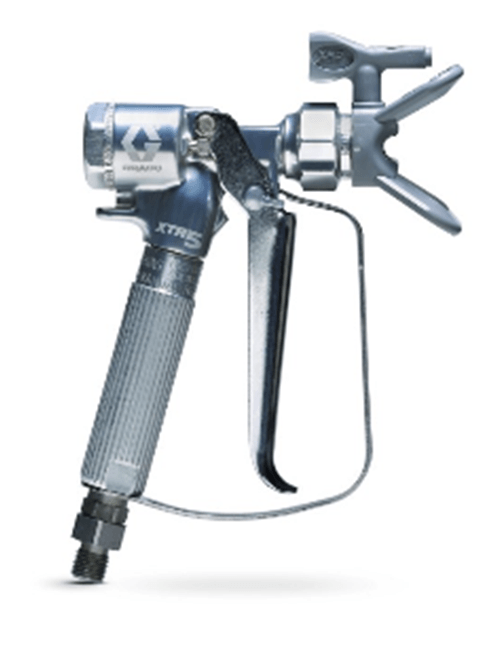

243-283 Graco Silver Plus Airless Spray Gun

ALH25253300 1/4″ X 25’ Airless Hose (3,300 PSI)

ALH25503300 1/4″ X 50’ Airless Hose (3,300 PSI)

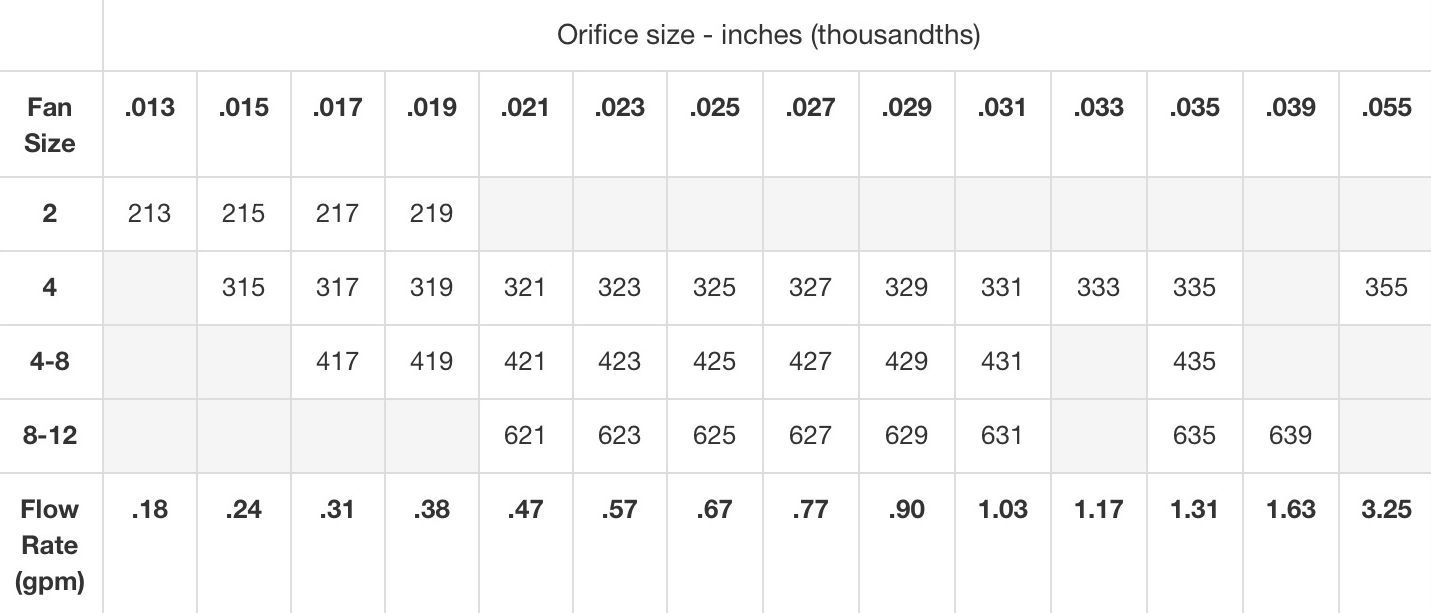

27115 Back Pressure Assembly (Less Tip)

27116 Back Pressure Orifice (0.18”)

21717 Back Pressure Orifice (0.31”)

27118 Back Pressure Orifice (0.39”)

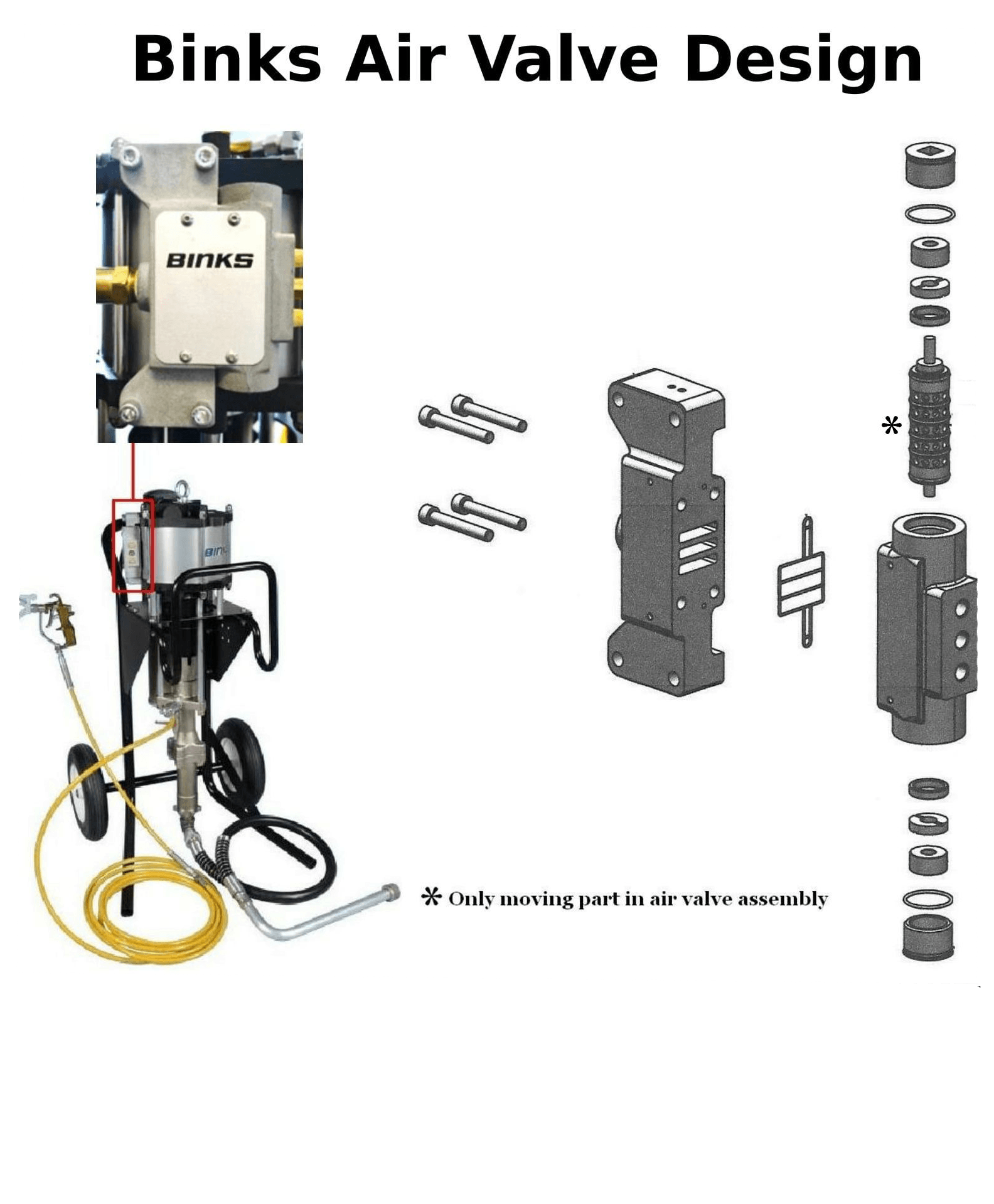

Airless Pumps - Binks®MX Series Airless Pumps

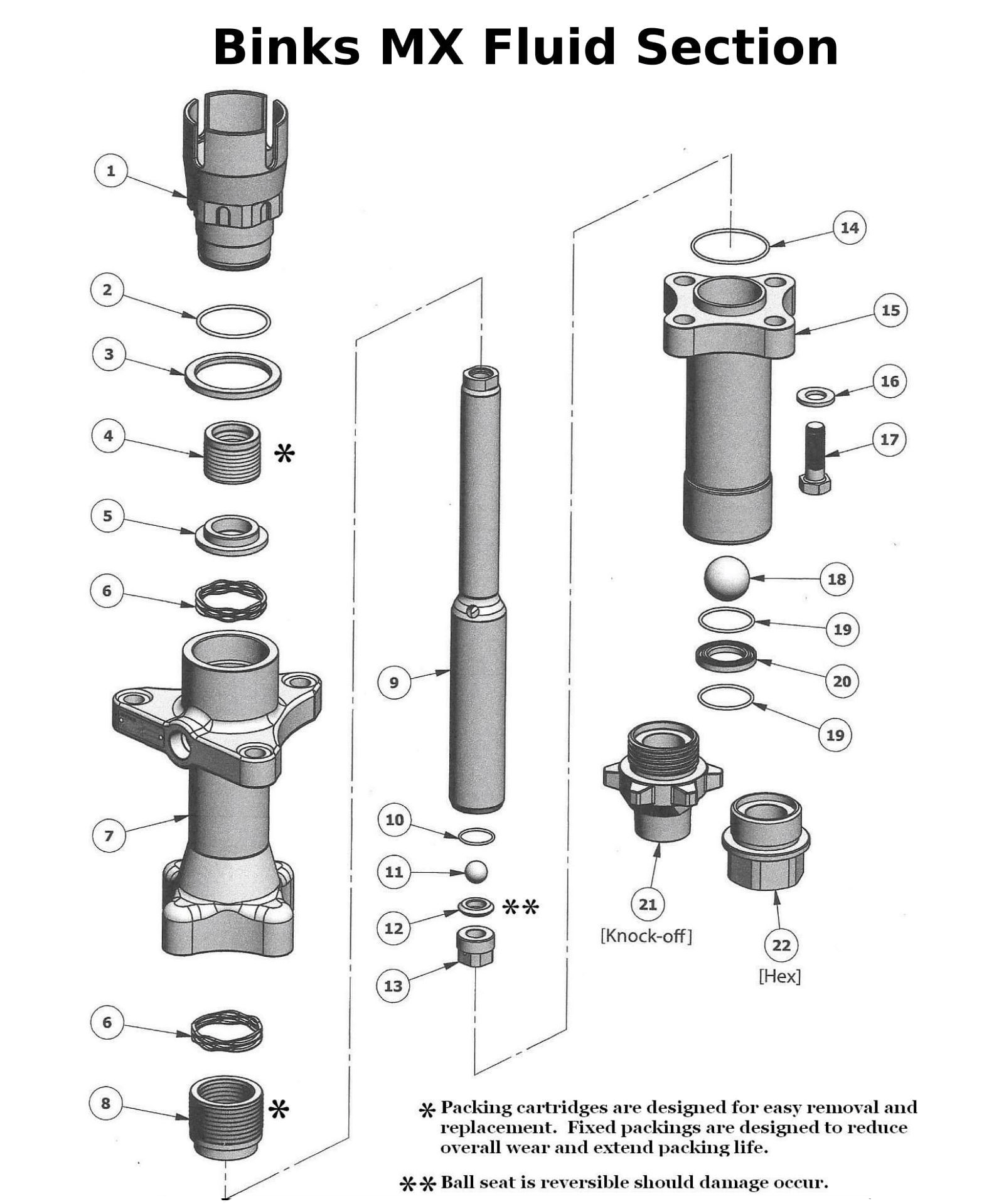

When using airless pumps for coating application, few things are more important than performance, reliability, and ease of maintenance. Binks has been a leader in airless pump technology for decades and throughout this time their focus has been creating reliable equipment that outlasts and outperforms. The MX Pump is the culmination of years of real-world industry testing and practical engineering.

The information listed below will help to illustrate the major reasons why MX pump technology is superior to most pumps found on the market. We have included breakdowns of all major components to highlight the pump’s simplicity of design and unbeatable user-friendliness.

Simplicity of Design

Fewer Parts = Less Troubleshooting = Fewer Repairs

Quick breakdown and repair of pump = less downtime

Fluid Section Repairs

- With proper tools, the MX lower end can be removed from the pump in just a few minutes. After that, complete stripping down and repacking of the fluid section can be achieved within a short amount of time.

- Packing cartridges make installation of upper and lower packing sets quick and effective.

- Piston rod has ceramic coated upper and lower sections that significantly reduce friction wear and prolong packing life. Stepped rod design eliminates the need for additional cylinder.

- Because packings are fixed in place, rod and upper/lower housings do not require precision grind to function properly. This means that if the fluid section is locked up or “trashed”, it is likely that you will not have to replace the upper/lower housing.

Air Motor Repairs

- MX air motor does not require lubrication.

- Poppet valves are most common wear item on air motor. Can be replaced in minutes.

- Trouble-free operation – spooling valve has no seals or springs, and magnetic detents prevent stalling. Large valve body design eliminates risk of freezing.

- Runs quieter. Runs longer. Runs Better!

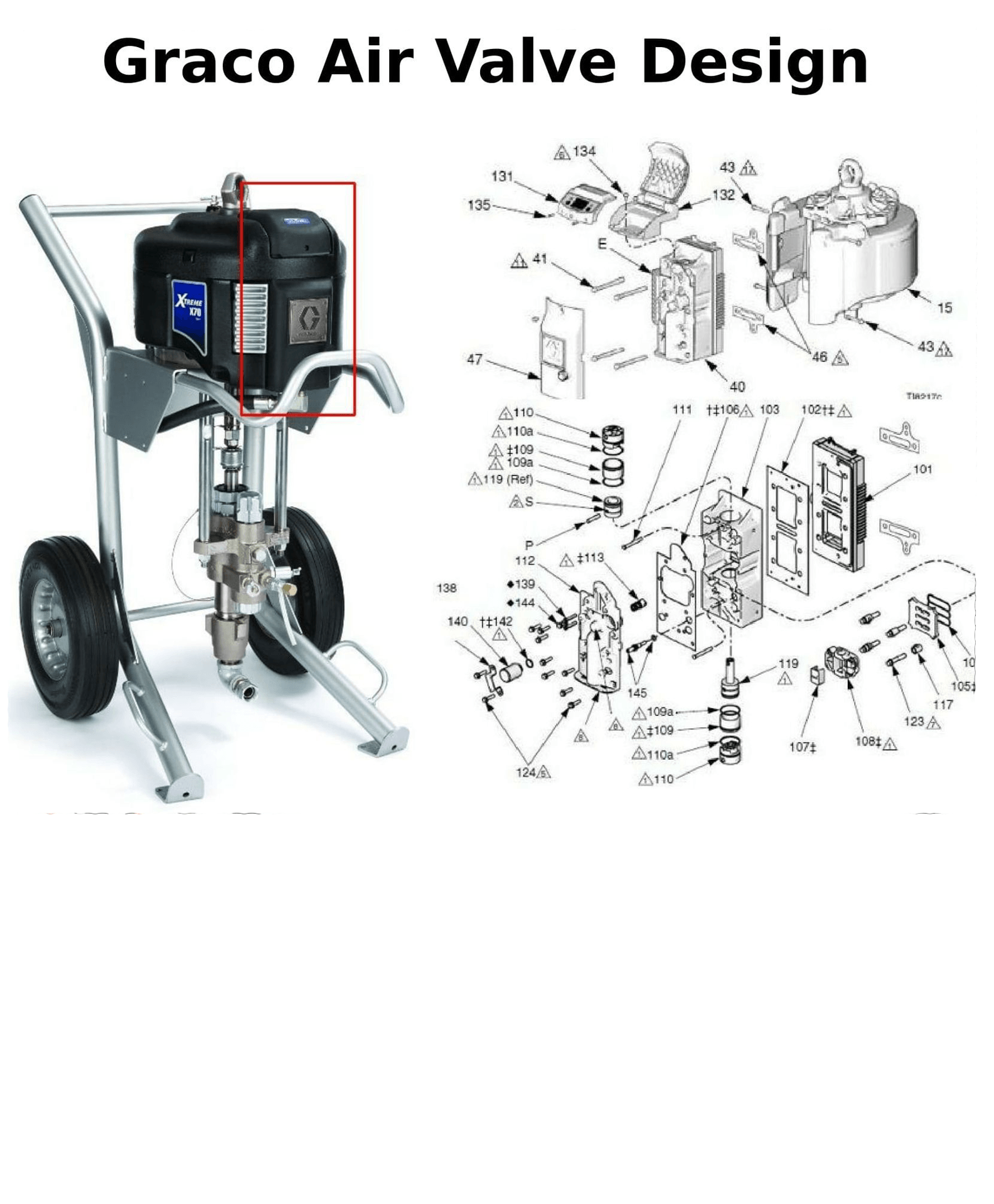

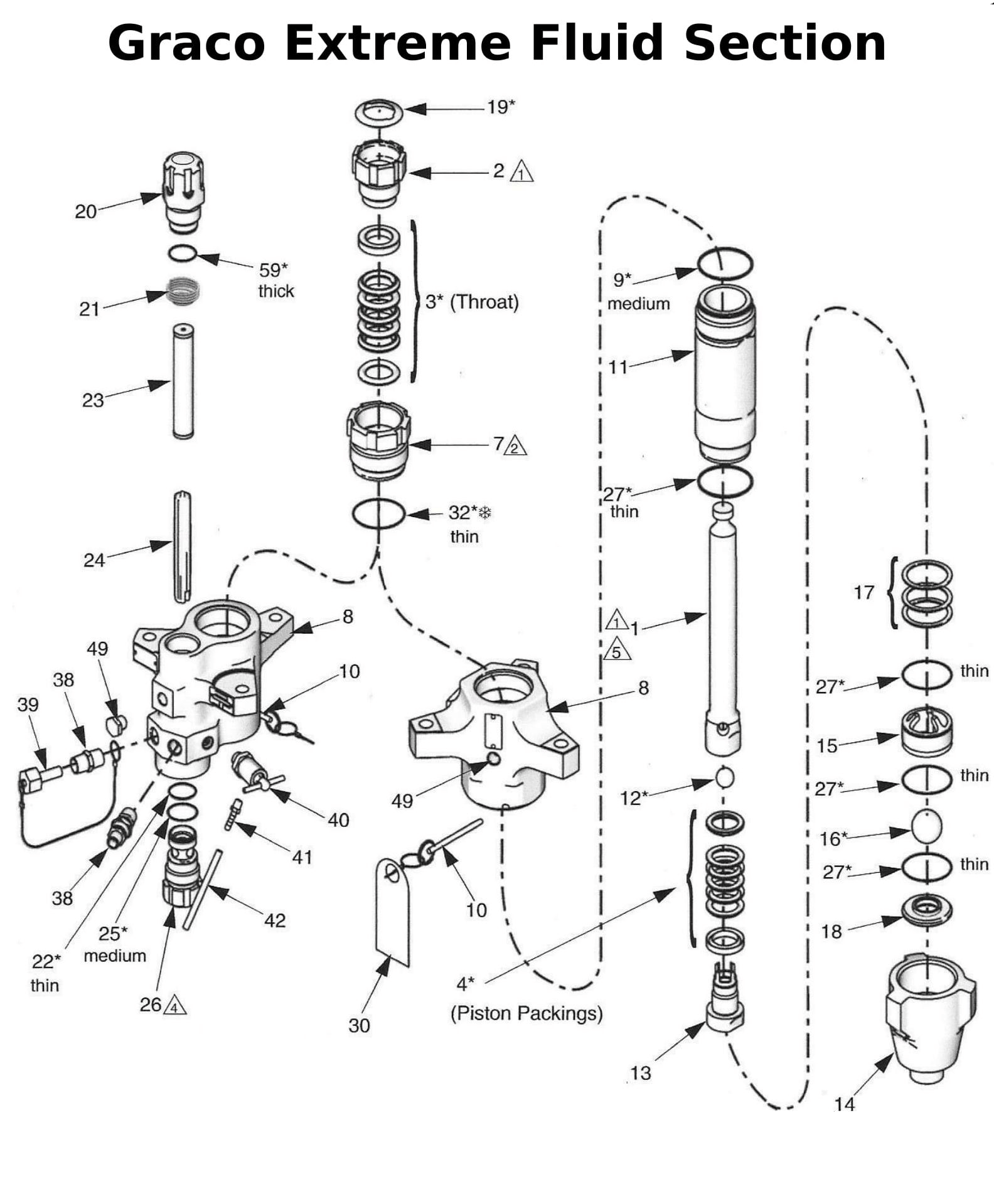

Graco Extreme®NXT ® Industrial Pump Series

Graco Xtreme NXT high-pressure air-operated airless sprayers provide excellent durability that helps get through the toughest jobs. The Graco Xtreme easily handles the toughest protective coatings and corrosion control materials. These pumps are available with a variety of options to assist with data tracking, paint consumption and establishing exact pressure settings. For those who prefer to eliminate paint waste and cumbersome siphon hoses, Graco offers a cart mounted hopper system to easily hold and feed up to 6 gallons of material directly into the fluid inlet on the pump. Consult the Xtreme airless pump and accessories brochures below for more information and available options.

Graco Commercial Pumps

We carry the complete line of Graco commercial grade electric and gas airless paint and texture sprayers. These units are designed with light duty and residential/commercial applications in mind. With a large variety of pump sizes and output options available, we have the pump that’s right for your job size. Please consult the brochures below for a listing of all the current models available and don’t hesitate to contact us if you have any questions.

Graco Line Stripers

Graco Line Lazer striping machines are a fast and efficient way to apply striped coatings to any surface. These machines are suitable for use at airports, athletic fields, parking lots, bike paths and any other application where boundary designations are required. Graco offers walk-behind and self-driven models to accommodate jobs of all sizes. Check out the Line Lazer brochure below for the complete product offering.

We are the headquarters for Airless Products. Call T-Tex today for prompt service.